- Order number: TPPSCF1

- commodity code: 39169050

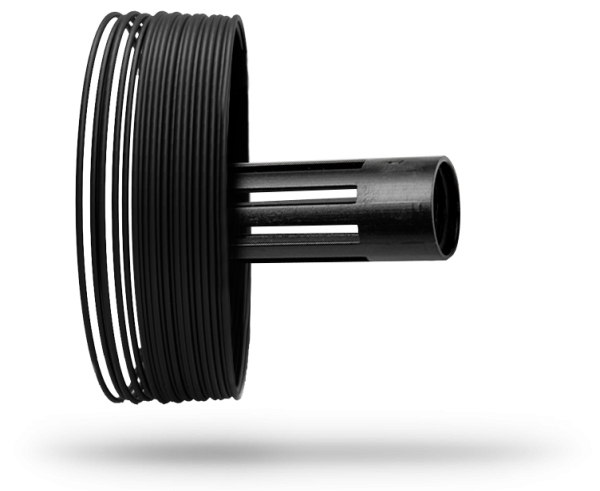

TreeD PPS CF 3D Printing Filament

PPS CF is a polyphenylene sulphide reinforced with 15% carbon fibre directly in the filament.

The added carbon fibre is more resistant than natural PPS. Lightweight and versatile in printing, it does not deform.

It is an ultra-performance filament that has a mechanical and metallic feel. It is suitable for most commercial printers using FFF and FDM technology.

Easy to print, even with an open chamber. Be sure to keep the temperature high during extrusion and use a steel extrusion nozzle like Widia. No Teflon surface.

PPS CF TECHNICAL DATA

Pressure temperature: 305-320°C

Sheet temperature: 100°C

Plate coating: kapton tape, abs glue, buildtak™.

Maximum printing speed: 35 mm/s

Material on roll: 1000g

Diameter: 1.75mm

In general, filaments made of PPS Carbon can be processed on conventional 3D printers with FDM / FFF Technology.

PPS Carbon is a reinforced polyphenylene carbon fibre developed for 3D printing.

For best results, we recommend pre-drying the filaments at 120° for 4-6 hours. For spools up to 1 kg, the drying time should be extended.

Do not leave the filament in the nozzle for more than 20 minutes. If this causes the temperature to drop below 230°, it is better to switch off the thermal control.

(1) The recommended print settings are only a recommendation for general use. Each printer needs a specific set, nozzle temperature, bed temperature, etc.

(2) 0.5 mm is the minimum diameter of the nozzle reinforced with carbon fibres.

Carbon fibres are abrasive, we recommend using a nozzle made of hardened or tempered metal, such as Widia, or wear resistant or a wear resistant inner surface, such as ceramic or other.

DO NOT use a teflonised surface!

| Material: | PPS CF |

| Color: | black |

| Radius: | 1,75 mm |

| Weight: | 1000 g |